The mmc driveshaft is made of an aluminum matrix reinforced with boron carbide allowing the critical speed of the driveshaft to be raised by reducing inertia.

Boron carbide ceramic metal matrix.

Ultramet has unique capabilities to deposit proven interface coatings of oxides nitrides and carbides by ultraviolet activated chemical vapor deposition either in single or multiple layers.

Download full ultrafine grained aluminum and boron carbide metal matrix composites book or read online anytime anywhere available in pdf epub and kindle.

Alumina fibers can be given a surface coating of silica to improve tensile strength.

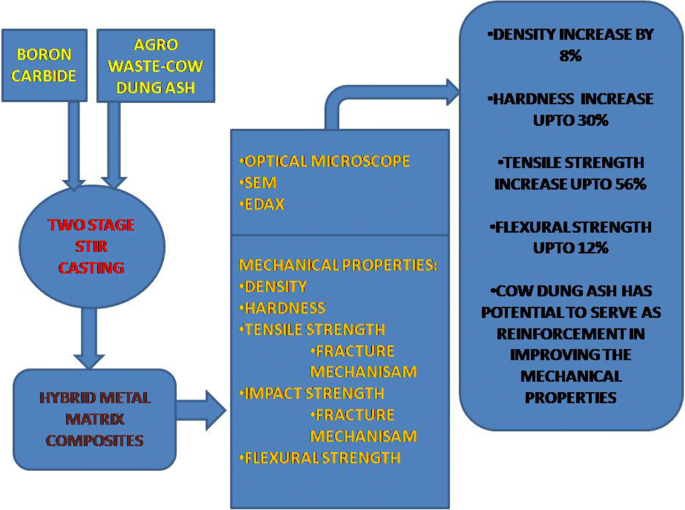

Increase in percentage of boron carbide from 2 to 7 resulted in increase in the micro hardness of the metal matrix composite significantly and the uniform distribution of particles in metal matrix was revealed by the micro structural examination.

Ford offers a metal matrix composite mmc driveshaft upgrade.

As an example tic particles 25 weight may be uniformly dispersed in an al 2 o 3 matrix to yield a conducting ceramic.

With a vickers hardness of 30 gpa it is one of the hardest known materials behind cubic boron nitride and diamond.

This reaction results in the evolution of co and the formation of the metal boride ceramic.

Or mixture thereof in a non electrically conducting ceramic matrix.

It is perhaps the hardest of materials which can be processed as a conventional ceramic and its applications are concentrated where hardness is the principal requirement including grit blasting nozzles bearings light weight ballistic armor etc.

Metamic classic is a discontinuously reinforced aluminum boron carbide metal matrix composite material designed for neutron radiation shielding applications.

The proportion of the conducting.

Boron carbide b 4 c is one of a number of boron carbon compounds but is the one most frequently used as a ceramic material.

The mmc driveshaft has become a common modification for racers allowing the top speed to be increased far beyond the safe operating speeds of a standard aluminum driveshaft.

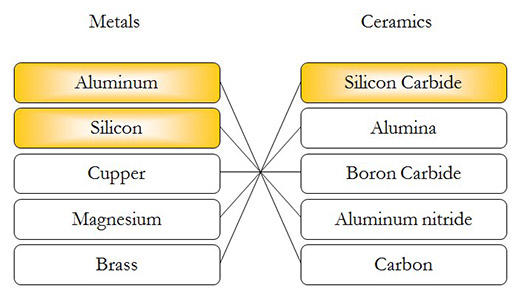

Radiation shielding abrasives armour structural engineering ceramics metal matrix composites.

For example bo ron fiber can be coated with boron carbide and silicon carbide reaction barriers to prevent diffu sion and chemical reactions with the matrix that decrease the strength of the composite.

Boron carbide chemical formula approximately b 4 c is an extremely hard boron carbon ceramic and covalent material used in tank armor bulletproof vests engine sabotage powders as well as numerous industrial applications.

Metamic radiation shielding products are fabricated using powder metallurgy technology from nuclear grade boron carbide astm c750 type 1 and high purity aluminum powder.

Click get books and find your favorite books in the online library.

Fiber interface coatings are critical to any fiber reinforced ceramic matrix composite system.

Additional information on boron carbide boron carbide is a black crystalline compound one of the hardest known materials and is the hardest material produced in tonnage quantities.